Indsutries

- Crusher Industry

- Pata Mills

- Cement Industry

- Automotive Industry

- Mining Industry

- Gear Box

- Agriculture

- Motor Pumps & Compressors

- Sponge Iron

- Lathe Machine

- Sugar Industry

- Food Processing

- Rolling Mill

- Pulp & Paper Mill

- Steel Industry

- Construction & Heavy Equipment

- Wind Energy

- Aerospace

- Rail & Transit

- Infrastructure

Pata Mills

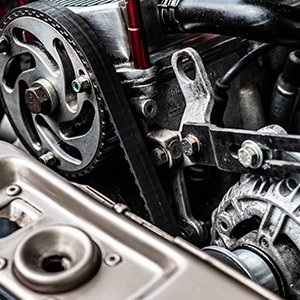

Pata mills for rolling of steel differ in many aspects with each other. The rolling mills are of different sizes and capacities and they roll steel materials of different cross-sections, sizes and qualities and in material conditions which are either hot or cold and they have different configurations and speeds of rolling.

These mills, with harsh operating conditions, need bearings that reduce friction and provide adequate support for effective rolling with minimum of energy loss. DYZV bearings are specifically designed to withstand high rolling loads, heavy shocks, varying speeds, and high temperatures. They also have enhanced contact surfaces and material strength properties that provide high performance so that the mill downtime can be reduced.

Types

- Spherical Roller Bearings

- Four-Row Cylindrical Roller Bearing

Features & Benefits

- High Radial Load Capacity

- Superior Stiffness for Precision

- Excellent Resistance to Shock and Vibration

- Minimized Edge Stress

- Enhanced Operational Reliability in high-temperature environments

- Longer Service Life between roll changes

Applications

- Cold Rolling Mill

- Hot Rolling Mill

- Cold Coil Mill

- Mill Leveler & Pinch Roll

- Cold Aluminium Coil Mill

- Reversible Coil Mill

- Foil Mill

- Heavy Duty Crane

- Backup Rolls

- Plate Mill

- Heavy Duty Gear Box